Demand planning is a both an art and a science – get it right, and your supply chain runs like clockwork. Get it wrong, and you’re left dealing with stockouts, surplus inventory, and unhappy customers.

Ever walked into a store and easily found what you needed? That’s demand planning done right. But achieving this level of efficiency is no easy task: it requires factoring in countless variables, from shifting consumer trends to supplier constraints, all while staying agile in the face of unexpected disruptions (looking at you, COVID-19).

table of contents

- What is demand planning

- Demand planning for inventory management

- The importance of forecast accuracy

- Collaborative planning for Supply Chain optimization

- Best practices for implementing demand planning

- Demand planning software: what Rulex Platform can do

- A real-life demand planning example

- The future of demand planning

What is demand planning?

Think of demand planning as a balancing strategy, where the goal is to accurately forecast customer demand so that the right products are available at in the right place, in the right quantity, at the right time. To get there, demand planning relies on sales trends, market shifts, and lead times to keep inventory levels optimal.

Sounds complicated? It is. Supply chains are deeply interconnected, and a single miscalculation at any stage can set off a domino effect that will leave businesses scrambling or customers empty-handed.

Demand planning for inventory management

Whether literal or figurative, every product has an expiration date. Effective demand planning is necessary for knowing how much inventory to keep to meet customer needs, without the financial drain of overstocking or the lost revenue from stockouts.

Poor inventory management can have a massive financial impact: according to the global consulting company McKinsey, companies that can predict customer behavior more accurately reduce inventory levels by 20%, leading to significant reductions in inventory costs [1,2].

The importance of forecast accuracy

The value of accurate demand planning extends far beyond inventory management. Forecasting is also a strategic tool for financial planning. Critical business decisions such as pricing strategies, revenue projections, and capacity planning are directly tied to the demand management process. A precise forecast helps businesses make data-driven decisions that foster growth.

Collaborative planning for Supply Chain optimization

Supply chain efficiency is a team effort, where even the best forecasts can fall short if there is poor alignment between departments.

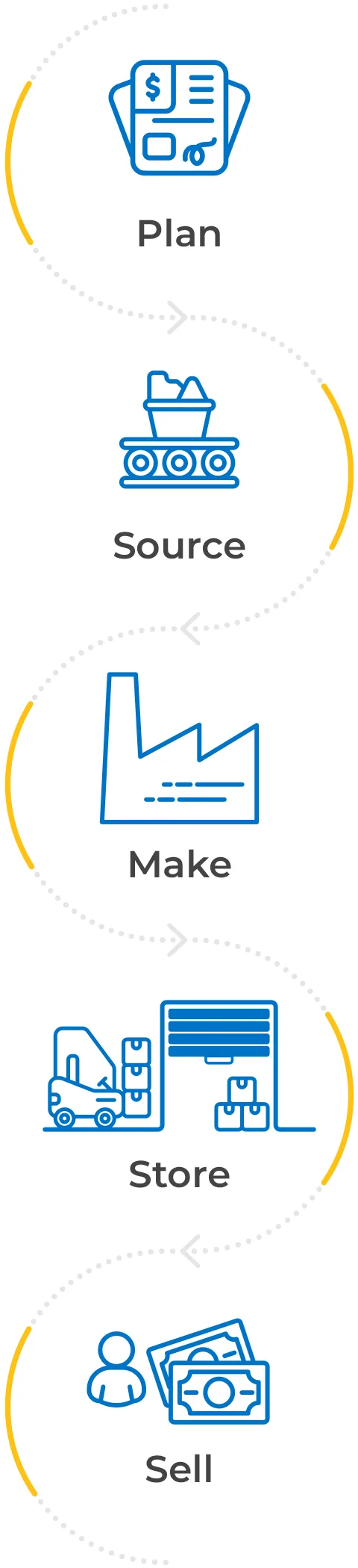

To understand why the demand management process is not an isolated task, let’s break down the complex web of a supply chain. It all starts with suppliers delivering raw materials to manufacturing facilities, where products are produced. From there, finished goods are sent to distribution centers, awaiting shipment to retail stores or directly to customers. Unexpected disruptions at any step of the chain can throw the entire system off balance. Imagine a scenario where the sales team anticipates high demand, but procurement fails to secure enough raw materials. Or if production increases, but warehouses are already at full capacity. Even identifying which finished products drive the highest profits through an ABC analysis is crucial for knowing which goods to prioritize at the very first step of the chain.

So, how do businesses navigate these challenges and build a more resilient approach to demand forecasting? By following industry best practices.

Best practices for implementing demand planning

At its core, forecasting relies on two types of information: certain data, such as known warehouse stock, and uncertain factors, like fluctuating customer demand. Success depends on estimating these uncertainties and making informed decisions to maintain the right stock levels. Identifying an issue in your demand planning is not enough – if the software used to make predictions takes too long to adjust, your business risks missing sales opportunities and becoming trapped in operational inefficiencies.

Let’s break down the steps to mastering demand planning:

Collecting and preparing data

Strong demand planning starts with high-quality data. This involves collecting information from different sources and formats, integrating it, and cleansing it for analysis. The faster and more adaptable your system, the better.

Defining process models

Should your business prioritize aggressive stockpiling or a lean inventory approach? Determining the best strategy is rarely straightforward. The same applies to choosing the right forecasting model for each product, as not all products behave in the same way! For example, printer cartridges tend to follow a stable and predictable pattern, while high-end smartphones see sudden demand spikes and shorter life cycles.

Choosing the right software

Invest in demand planning software with advanced AI and ML algorithms, as well as other capabilities that enhance forecast accuracy, decision-making, and allow for quick adjustments. A robust platform should support real-time recalculations and generate multiple demand forecasts based on specific products, adjusting to different assumptions and probabilities.

Implementing and monitoring

Use automated workflows to test multiple forecasting models, selecting the most effective one, and check if it’s still grounded in reality by monitoring sales and new external variables. Even better if the solution can be integrated with other supply chain tools already in-use.

Demand planning software: what Rulex Platform can do

Rulex Platform is an all-in-one decision intelligence software that allows companies to seamlessly manage every aspect of demand forecasting – orchestrating data, improving and supporting decisions, and automating processes. All with the flexibility to easily integrate into the existing infrastructure, thanks to capabilities like APIs. Designed with a drag-and-drop interface, Rulex Platform allows non-technical users to mix and match the advanced technologies of its toolkit to create tailored solutions. As a plus, it also includes an integrated dashboarding and custom UI component, providing a smart way to visually interact with underlying data and solutions.

From mitigation sources planning, to replenishment optimization and simultaneous production and work shift planning, Rulex Platform is trusted by companies and supply chains worldwide in their digital transformation journey (you can explore some success stories in our Supply Chain case studies e-book). But first, let’s examine a practical example of demand planning in action.

A real-life demand planning example

Recently, a global pharmaceutical company turned to Rulex Platform to improve demand forecasting for several flagship products based on both historical sales and external variables such as temporal trends, the diffusion of seasonal viruses, and geographic information. Using AutoML, Rulex’s decision intelligence software automatically selected the best forecasting model, allowing for parallel testing of multiple strategies. The company’s domain experts could check what was going on and make adjustments at each point of the process, thanks to the inherent transparency of Rulex’s technology.

The solution delivered demand forecasts over a three-month forecasting horizon, updated dynamically to incorporate new data and ensure that the latest trends were always factored in. The results spoke for themselves: accurate forecasts (average error below 10%), smooth integration into inventory and logistics systems, and a process that helped the company make smarter decisions.

But what about demand forecasting for newly launched products with no sales history? In another real-world case, a furniture company used Rulex Platform’s advanced analytics and clustering tools to tackle this challenge. The software analyzed key attributes of new items, such as category, brand, and size, to find similarities with existing products that had sales data. By comparing these attributes, the company was able to generate an initial demand forecast, even in the absence of historical sales records.

Once you’ve perfected demand forecasting, the next step is inventory optimization – if that’s something you’re exploring, we’ve got an article on it too.

The future of demand planning

Companies investing in advanced forecasting solutions, such as AI-driven machine learning and predictive analytics, will stay ahead of market shifts, contributing to a global economic impact of $9.2 trillion by 2029 [3].

Is your demand planning strategy ready for what’s next? Get in touch today to find the right solution for your business.

Find the right supply-demand balance