Smart manufacturing

Optimizing manufacturing performance while maintaining quality

Amidst a notable escalation in both material and energy expenses, manufacturers find themselves confronted with unyielding demands to enhance performance within their production facilities while maintaining product quality.

Rulex offers a strategic advantage by harnessing the full potential of data to build cutting-edge solutions, spanning from advanced asset management and predictive and preventive maintenance, to predictive quality.

Enhancing performance with

future-ready technology

Powered by Rulex Platform, manufacturing companies have improved operations by implementing solutions ranging from predictive product quality to preventive machine maintenance, process planning, and more.

Download our use case e-book to explore some of these success stories.

WHY RULEX

SOLUTIONS

USE CASES

FREE RESOURCES

rulex platform

Why Rulex is different

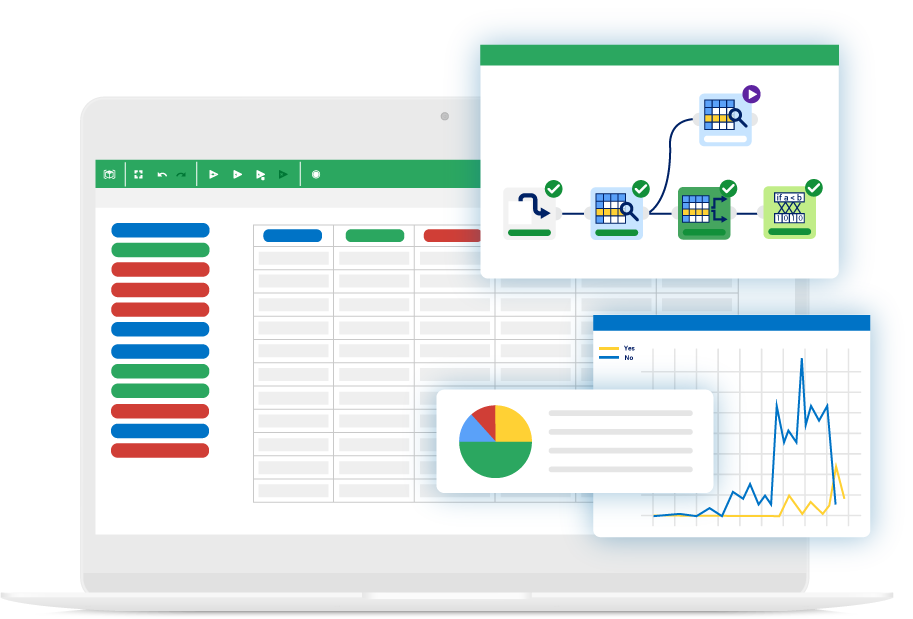

Speed

Rulex Platform outpaces competitors by processing data 10 to 100 times faster, even in intricate scenarios with millions of data rows. This agility makes it the ideal tool for tackling the challenges of IoT solutions, which require managing and extracting value from extremely large volumes of data.

Flexibility

Rulex Platform integrates seamlessly with multiple data sources, ranging from machinery sensors to maintenance reports, master and production data.

The multiple sources can be merged into a single point, quickly creating a unified view of all processes.

Simplicity

Domain experts can utilize the simple WYSIWYG drag-and-drop interface to independently extract insights from consolidated data.

This efficient method saves time and eliminates IT bottlenecks, enabling users to independently develop new solutions to streamline processes.

Solutions

What we do for manufacturing

Predictive maintenance

Analysing the conditions that lead to malfunctions to proactively prevent breakdowns using XAI and Rule-Based Control.

Predictive quality

Predicting and improving the quality of finished goods using XAI and Rule-Based Control.

Asset management

Reconciling data from multiple sources, to form the foundation for preventive strategies and digital twins.

Predictive & preventive maintenance

Rulex’s XAI-based predictive maintenance solution can help identify the values of equipment parameters that precede failures, thereby identifying the underlying causes, and detecting failures before they occur. The Rule-Based Control task is then able to recommend timely preventive actions, minimizing downtime and reducing maintenance costs.

Predictive quality

Product quality is critical in manufacturing, directly impacting customer satisfaction, brand reputation, and reducing costs associated with returns, repairs, and warranty claims.

Rulex enables organizations to build and implement custom predictive quality strategies, through its XAI technology and Rule Based Control task. Together, these solutions analyze defects in historical data, pinpoint the parameters that together improve efficiency, and recommend actions to be taken to ensure high-quality products.

Asset management

Industry 4.0 has revolutionized asset management in manufacturing by introducing advanced technologies, such as the Internet of Things (IoT), big data analytics, and AI. This innovation has lead to a wealth of fresh information, which needs to be efficiently gathered, aggregated and reconciled to create a unified view of machinery and equipment.

Rulex’s data agility capabilities enables organizations to perform efficient asset management by skilfully orchestrating vast amounts of heterogenous data from sensors, alarms, reports and plans, consequently enabling the adoption predictive maintenance strategies, improving overall equipment effectiveness (OEE), and laying down the foundations required to build digital twins.

USE CASES

Making manufacturing more competitive

PREDICTIVE QUALITY IN SOLAR PANELS

Efficiency is crucial for solar panels, whose production involves multiple stages with different plant machines. Altering machine parameters can affect solar panel performance.

Rulex provided a major energy company with an efficient predictive quality solution to integrate information from production machines, identify key parameters for production quality, and extract predictions from data.

Thanks to Rulex’s native XAI algorithm, and Rule-Based Control task, more than 100 parameter values were identified which could be tweaked to increase panel quality and performance.

Enabling construction of digital twins

Thanks to its foundational asset management capabilities, Rulex enabled a major manufacturing organization to build a global unified picture of one of their plants.

Rulex enabled its customer to gather and aggregate data from heterogenous sources, ranging from master data to IoT sensors, maintenance reports, alarms and production reports, and create a digital twin of the plant.

Once the all available information on each machine had been reconciled into this single view, it was then possible to implement an efficient predictive maintenance strategy to predict and prevent equipment breakdown.

PREDICTIVE MAINTENANCE TO AVOID BREAKDOWNS

Rulex designed a predictive maintenance solution for an international manufacturer to help them identify the condition of their trenchers. Using historical data generated by sensors on the machines, the solution was able to predict whether equipment was potentially close to breakdown and why, with an accuracy of over 90%.

Rulex’s technology consequently provided timely instructions on how to avoid breakdowns, such as lowering engine temperatures.

Free resources to dive into

ARTICLE 3 tricks to working on a Bill of Materials (BOM) in data tables

3 tricks to working on a Bill of Materials (BOM) in data tables

GUIDE Getting to grips with your master data

Getting to grips with your master data

VIDEO Rulex RDC: highly performing supply chains with top quality data

Rulex RDC: highly performing supply chains with top quality data

Make manufacturing more competitive