Unlocking supply chain excellence

From agile data orchestration to optimum plans in minutes

In the intricate landscape of managing producers, suppliers, couriers, warehouses, and product lines amidst global and day-to-day disruptions, the pursuit of streamlined planning and operational efficiency can often appear elusive for many supply chains.

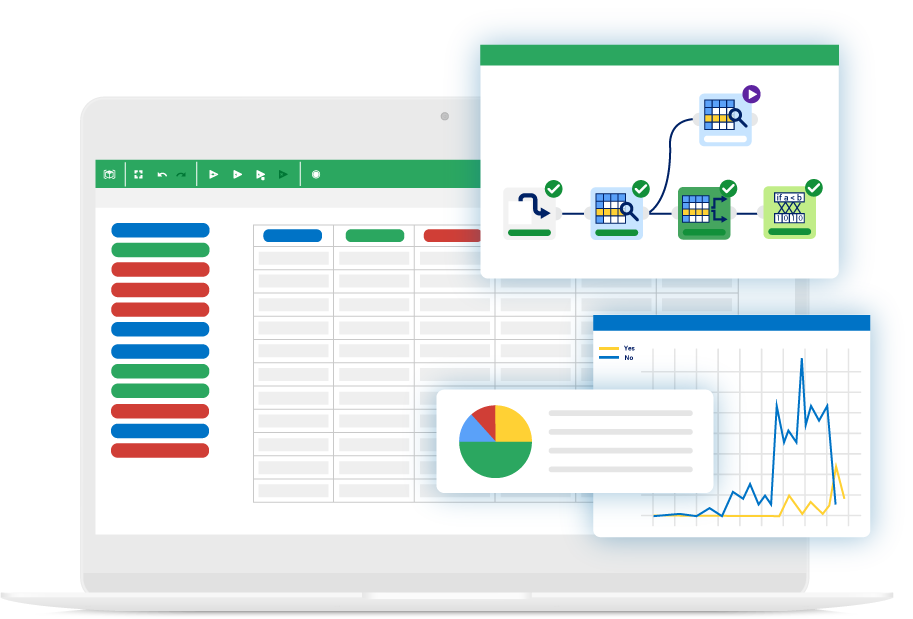

Rulex Platform empowers supply chains to achieve excellence by unlocking the full potential of their data, through each step in the end-to-end process. From seamless data orchestration and reconciliation, to enhancing data quality through domain knowledge and explainable AI, and discovering the optimum solution to any business process through ground-breaking optimization capabilities.

Transforming global supply chains

Powered by Rulex Platform, global supply chains have enhanced process efficiency by implementing solutions for dock optimization, mitigation sources, and simultaneous product and packaging planning.

Download our use case e-book to read about some of these success stories.

WHY RULEX

SOLUTIONS

USE CASES

FREE RESOURCES

USE CASES

rulex platform

Why Rulex is different

Speed

Rulex Platform processes data 10 to 100 times faster than competitors, even in complex scenarios with millions of rows of data. It swiftly identifies solutions, generating plans in minutes for timely and up-to-date enterprise-level outcomes.

Flexibility

Unlike rigid APS and TMS systems, Rulex Platform adapts seamlessly to business requirements, client data and existing infrastructure. This ensures customized solutions with a rapid, non-disruptive implementation process.

Simplicity

With a WYSIWYG, drag-and-drop interface, Rulex Platform enables independent control over all aspects of data management in a single environment. This saves time and money and eliminates reliance on external groups for changes.

Solutions

What we do for the supply chain

MASTER DATA MANAGEMENT

Ensuring consistent and well-structured master data across the entire organization.

OPTIMIZATION

Providing the optimum solution to any business problem without mathematical formulas and scripts.

DECISION INTELLIGENCE

Leveraging eXplainable AI, rule engine, and AutoML technology to improve decision-making.

Running successful MDM strategies

All essential supply chain operations, from inventory management to demand planning and procurement, depend on well-managed master data, which handles company-critical information.

But as organizations grow in complexity, integrating new acquisitions and geographical locations, master data may become difficult to collect and compromised by inconsistencies and duplicated records.

Rulex Platform enables the implementation of successful MDM strategies, including smart data orchestration, advanced quality control, and data security and governance, ensuring consistent and well-structured master data across the entire organization.

Optimizing supply chain processes quickly

Rulex Platform enables planners to express business problems as simple if-then rules, while automatically generating and applying constraint matrices without writing a line of code.

This solution has empowered many citizen developers to independently optimize complex scenarios, such as planning production according to worker shifts, and even prioritizing specific constraints.

Improving decision-making

Rulex maps the right technological solution to each business challenge, choosing from a wide range of tools, including its native eXplainable AI, machine learning algorithms, an efficient rule engine and a user-friendly configurable AutoML.

This wide array of tools enables business users to make fast and accurate decisions while remaining in full visibility and control.

RULEX-OMP PARTNERSHIP

OMP and Rulex are collaborating to enhance data quality management in supply chain planning.

We are jointly creating an OMP-Rulex connector, leveraging Rulex Platform’s data consolidation and validation capabilities to streamline the deployment of OMP’s Unison Planning™ Solution. The focus is on improving master and operational data quality through cleansing and validation functionalities, facilitating streamlined integration into the OMP digital framework.

This partnership extension reflects the commitment of both companies to address data management challenges and provide optimal solutions for informed decision-making in supply chain planning.

USE CASES

Unlocking supply chain excellence

FACILITATING DATA ORCHESTRATION

Multinational corporations grapple with the complex task of managing master data dispersed across diverse local and cloud-based locations, such as ERP systems with differing units, formats, and languages.

Rulex has efficiently helped global supply chains by collecting, aggregating, and harmonizing data from these sources, standardizing information where industry standards diverged for the representation of the same values.

For example, product codes of varying length were easily transformed to align with the requirements of vertical software solutions.

IMPROVING WAREHOUSE REPLENISHMENT

Warehouse replenishment is traditionally cumbersome and error-prone, leading many companies to explore vertical planning systems.

Rulex stands out from competitors by automating 100% of planning decisions, offering unparalleled adaptability to customer scenarios and dynamic markets.

In a recent application at a F50 supply chain client, Rulex implemented a cascade solution to efficiently manage over 130 different priorities in warehouse replenishment. The solution resulted in an 8% reduction in stock/overstock, decreased planner time requirements, and $100K daily savings.

OPTIMIZING PRODUCTION AND PACKAGING

Efficiently optimizing any supply chain area presents a challenge on its own. However, simultaneously addressing two interconnected production processes elevates complexity often beyond the reach of conventional tools.

Rulex employed one single, powerful task to optimize the production of both a beauty product and its packaging, maximizing production rates through this synchronized approach.

Constraints were defined using a plain English syntax rather than complex mathematical formulas. The task then automatically constructed the problem, making the solution ready for production in under a month.

Free resources to dive into our supply chain solutions

ARTICLE Supply chain optimization: what is is and how to do that with data

Supply chain optimization: what is is and how to do that with data

VIDEO Rulex Axellerate

Rulex Axellerate

VIDEO Rulex RDC: highly performing supply chains with top quality data

Rulex RDC: highly performing supply chains with top quality data

GUIDE

4 Pain Points in Supply Chain Transportation

VIDEO

3 tricks to working on a Bill of Materials (BOM) in data tables

Unlock supply chain excellence with the power of data