You’ve been eyeing that perfect shirt for weeks, only to find out it’s out of stock. Frustrating, right? But here’s the good news – thanks to inventory optimization, that same shirt is now back on the shelves, ready for you to snatch up.

In the fast-paced world of retail and supply chains, inventory optimization is the magic behind ensuring products are where customers want them, when they need them.

It goes without saying that stockouts and overstocking present a real nightmare for businesses, costing e-commerce companies an average of 11% of their annual revenue.

In this article, we’ll dive into how smart inventory solutions can prevent these dreaded issues, streamline operations, and deliver goods faster than ever.

table of contents

- What is supply chain inventory optimization?

- What are the key elements of inventory optimization?

- The challenges of traditional inventory optimization

- Inventory optimization strategies

- Real-life success: how Rulex transformed inventory optimization

- The road to better inventory planning and optimization

What is supply chain inventory optimization?

Inventory optimization is essentially a gigantic scale of demand and supply that companies trading goods must constantly balance. It involves strategically managing stock levels to maximize efficiency, minimize costs, and ensure customer needs are met. The goal is to have the right inventory available – not too much to result in extra storage costs in warehouses, but enough to buffer against unexpected disruptions.

Considering the many factors that could tip this scale in one direction or the other, finding the perfect balance is a challenging task. But not an impossible one.

What are the key elements of inventory optimization?

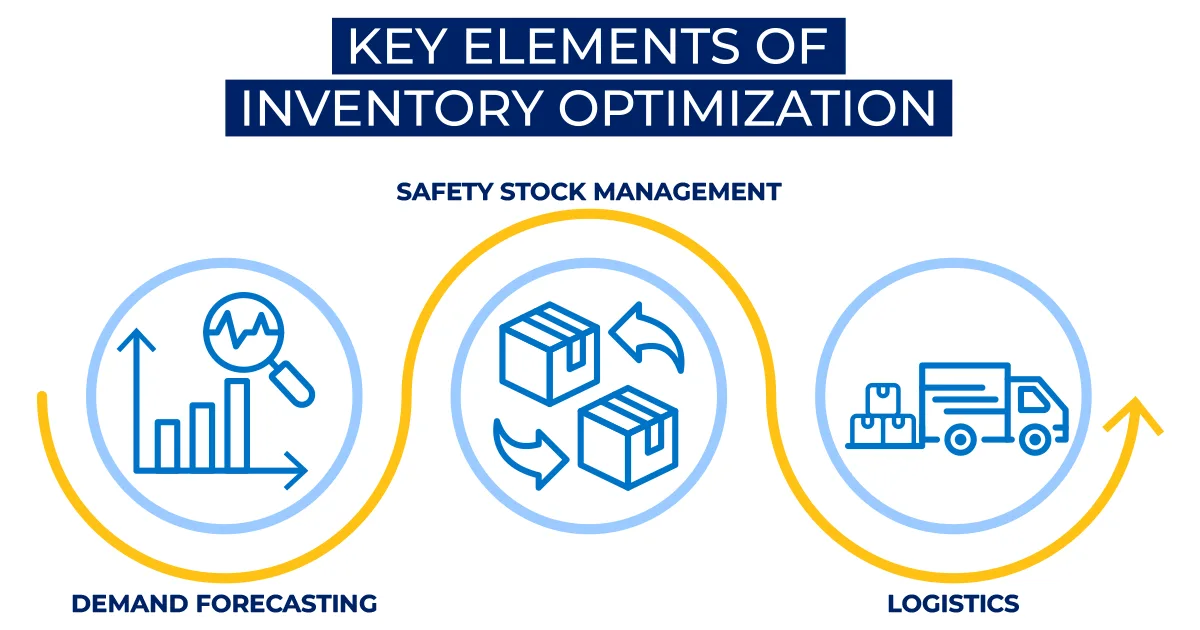

Inventory optimization is a multifaceted process that involves various players and stages. However, it can be broken down into three core areas: demand forecasting, safety stock management, and logistics. In other words, to stay efficient, businesses must anticipate future sales, determine the right stock levels, and ensure seamless distribution of goods.

Demand forecasting

This is the process of estimating future demand for a product, based on data. Even if we can’t predict the exact future, businesses can get close by combining historical sales data, customer and financial analytics, and external factors like seasonality and economic conditions.

Safety stock management

Closely tied to a product’s future sales, safety stock is an optimal inventory buffer that prevents stockouts while minimizing excess inventory, ensuring the company meets customer demand. It also acts as a cushion against supplier and production delays, demand fluctuations due to seasonal or unexpected events, and constraints during frozen horizon periods.

Logistics

A company may have sufficient stock to meet demand but not have it in the right locations. This is where logistics come into play. A well-organized flow of goods moving from production lines to various warehouses and distribution centers ensures that stock levels are strategically distributed, making inventory more efficient and accessible where it is needed most. Easy to say but hard to do, considering how complex it is to orchestrate shipment scheduling while also maximizing loads and choosing the best routes to save costs.

The challenges of traditional inventory optimization

Current inventory levels, storage capabilities, seasonal trends, good longevity, future promotional campaigns, supplier lead times and schedules – many are the factors to consider to always have the right amount of products ready to fulfill the market’s crazy demands.

Plus, even if we could make almost perfect demand predictions, another big challenge arises: having fast turnaround times to immediately act on, depending on the changing conditions. All of these factors make inventory optimization a highly intricate and demanding task, especially in the face of:

Fast-moving consumer demand

In the era of Amazon’s next-day shipping, consumers expect rapid delivery times, making it challenging for companies to predict and respond to shifting demand patterns quickly.

Increased competition

With even more players in the market, companies must find ways to stay ahead by improving their inventory management to meet customer expectations while controlling costs.

Supply chain disruptions

Unpredictable disruptions can halt the flow of goods, leading to stockouts, delays, and the need for costly contingency plans.

Technological challenges

It may sound shocking, but 67.4% of supply chain managers use Microsoft Excel to manage inventory, demonstrating how many are still relying on outdated methods instead of leveraging more efficient, automated technologies.

Inventory optimization strategies

This is an overview of some of the many strategies companies can implement to avoid the stockout and overstock nightmare.

ABC analysis

The ABC of any inventory optimization strategy is, of course, knowing your product, and this is what this method is all about. It classifies products based on their significance to the business, grouping them into three categories: A, B, and C. Category A includes the most valuable and critical items, whereas Category C consists of the least significant ones. By using this system, businesses can better manage inventory, ensuring they maintain appropriate stock levels and focus on the products that provide the greatest value to both their customers and the company.

Rulex has a long history of helping major retailers and supply chains implement this very strategy. See how easy it’s to calculate the most profitable and best-selling products in Rulex Platform in this dedicated webinar: Improving business strategy with ABC segmentation – Webinars – Rulex Community

SKU rationalization

Once a company has identified its Category C products through ABC analysis, the next step is to determine whether these SKUs (Stock Keeping Units) should be discontinued, modified, or retained in the product lineup. For example, a company might choose to keep a specific SKU because, despite its modest sales, it’s a niche product which cannot be found elsewhere, and consequently drives customer loyalty.

To streamline inventory in specific product categories, many retailers use Rulex Platform’s powerful Assortment Optimizer tool. This tool extracts and generates replacement rules from frequent itemsets, helping businesses determine how to replace items with equivalent alternatives for maximum benefit. By strategically removing products and replacing them with these alternatives, Rulex Platform helps businesses optimize their assortment, minimize revenue loss, and prevent customers from switching to competitors.

Demand forecasting

We have already mentioned the importance of estimating demand to align supply with market needs. This is another strategy that major companies have implemented using Rulex Platform. For example, Rulex supported a global pharmaceutical company in accurately forecasting sales for several flagship products through an all-in-one solution, which encompassed data pre-processing, modeling, and forecasting within a single platform.

To learn more about demand forecasting and its real-life applications, read our dedicated article.

Safety stock tuning

Downstream demand forecasting is the Holy Grail of safety stock tuning. In simple terms, it’s about determining the optimal amount of inventory to maintain based on both certain and uncertain factors (e.g., confirmed orders, expected orders, item availability, ect.).

Rulex has developed a solution that does exactly that. Using a series of simulations, it analyzes whether and how often the planned stock level could be exceeded. For example, if the estimated safety stock is set at 100 apples, but 20% of simulations show demand surpassing this amount, we will face a 20% risk of stockout if we don’t set a higher safety stock.

Replenishment optimization

Once safety stock levels are set, they must be carefully monitored to ensure smooth operations. Replenishment optimization is the strategy that makes this possible by managing restocking at the right time and in the right quantities. It ensures that inventory is replenished efficiently to meet demand while minimizing costs associated with stockouts, overstocking, and storage.

To address restocking challenges, Rulex has designed the Network Optimizer. This tool balances the workload distributed over a network, determining the amount of material to move and where to move it. Keep reading to see how this works in a real-life scenario.

Transport optimization

Good logistics ensure that products are where they should be when they are most needed. To help companies achieve this goal, Rulex offers an extremely powerful Transport Optimizer. Known as, Rulex Axellerate, this generates shipment schedules that help keep costs and delays down.

With extremely rapid computation times, Rulex Axellerate can create end-to-end, long-term transportation plans in under an hour. When applied to a major logistics network, the solution reduced expedited shipments by 70%. Watch the video to see how Rulex Axellerate works.

In addition to these two vertical solutions, Rulex offers a proprietary, general-purpose solver capable of tackling virtually any optimization challenge – from work shift scheduling to dock optimization — even across multiple domains simultaneously, such as production and packaging.

Real-life success: how Rulex transformed inventory optimization

At Rulex, we’ve worked with some of the world’s largest production and supply chain leaders to revolutionize inventory management. One standout case is a Fortune 50 supply chain company seeking help to maintain optimal stock levels across multiple warehouses and sites.

Traditional planning systems left up to 20% of planning decisions to be handled manually – an inefficient, time-consuming process. Rulex stepped in with an advanced replenishment solution, automating over 90% of these previously unmanaged decisions. With its powerful optimization tasks, Rulex reduced under – and overstocking by 8%, cutting costs by $100K per day in a single market region and lightening the planner workload by an impressive 75%.

By seamlessly adapting to real-world complexities, Rulex’s replenishment solution worked as a game-changer in creating a balanced, cost-effective, and agile supply chain.

Find out more about this specific case study and others in our e-book.

The road to better inventory planning and optimization

If you sell products, knowing where your inventory is, who wants to buy it, and where it needs to go is essential to your business’s success. However, this knowledge alone may not be enough without the right, flexible solutions to act on it.

With a vast array of predictive techniques and optimization solvers, Rulex provides supply chains with a powerful advantage, enabling highly customizable solutions for smarter inventory management.

Avoid the stockout and overstock nightmare